Have you ever wondered what goes into kids clothing manufacturing? Or how these things are even made? Or why you should care? Well, if you’re like most parents, the answers to these questions are probably no. But, it’s important to understand how these things are made. And more importantly, why you should care about that. In this article, you’ll learn what goes into kids clothing manufacturing, how much it costs, and why you should care. So, if you’re wondering how kids clothing manufacturing works, or why it’s important, read on.

What goes into kids clothing manufacturing?

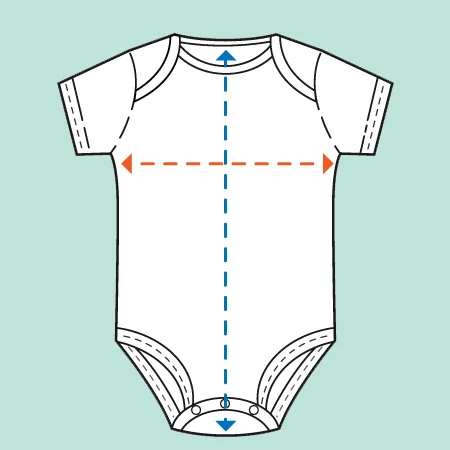

Kids clothing manufacturing is a process that starts with cutting fabric and ends with the final product. This article will talk about the steps in between, as well as why you should care about what goes into kids clothing manufacturing. The first step in kids clothing manufacturing is cutting fabric. The machine operator will cut the fabric to the design of the garment. Next, the fabric is sewn together by either hand or by machine. It’s then printed with a company name or logo. Finally, it’s inspected for any defects, like missing buttons, loose threads, etc., before shipping to stores around the world!

How much does kids clothing manufacturing cost?

The cost of kids clothing manufacturing varies depending on your order. Generally, the price is based on the minimum order quantity and the style of clothing you’re ordering. For example, the price for a 24-piece mixed order of printed t-shirts would be different than the price for 12 pieces of custom sweaters.

Kids Clothing Manufacturing can be expensive. But that doesn’t mean you should neglect it. There are many benefits to kids clothing manufacturing that make it worth every penny:

Why it’s important to know how kids clothing manufacturing works

Kids clothing manufacturing is important for a few reasons. First, it helps you understand your child’s clothes. You might notice that some clothes have tiny tags inside them with information about the material and where it was made. The tag tells you which company made the clothes and what country the clothes are from. This tag also tells you the material that was used in the clothing, like cotton or polyester.

Second, it helps you know what to expect when buying kids clothing. For instance, if a parent knew that a particular brand was known to use low-quality materials–like cotton–in their products, then they would probably avoid buying from that company altogether as they know that the quality of their product is not good.

Third, knowing what goes into kids clothing manufacturing can help you buy better quality clothes for your child. If your child wants more expensive clothes, then you might want to consider buying an item that has a higher cost because you know that they will last longer and be of better quality than an item with a lower price point. By knowing what goes into kids clothing manufacturing, you can make better decisions about how much money to spend on your child’s wardrobe.>>END>>

Final words

If you’re a parent, it’s important to know the steps that go into kids clothing manufacturing. It’s also important to understand why this is important, and how much it costs. In this article, you’ll learn about the various steps of kids clothing manufacturing and what goes into them. You’ll also learn about where these clothes come from and why care about that. And finally, you’ll see how much all of this costs. Hopefully, by reading this article you’ll learn some new things about kids clothing manufacturing, or at least get some reassurance that these clothes are made in a safe environment. So read on if you want to know more!